FAQ

Development, Design, Production- Home

- FAQ

Do you ever wonder what happens to all those plastics product that you put out on recycling day?

Except for handling by landfill, they have been used, recycled and re-purposed. They have become Post-consumer recycled material.

''Post-consumer recycled material'' is a kind of plastic raw material through the procedure of recycle, sampling, and category, smash, clean.

PP-PCR-All products in PP could add 30%~100% PP-PCR. Please find detailed information by clicking link of PP cream jar

PET-PCR-All products in PET could add 30% PCR. Please find detailed information by clicking link of PET/PETG cream jar

The material of PCR we adopted is certificated by Blue Angel, which means our customer could track the original source on PCR material and full production management system.

The theory of over Molding Jar / Bi-injection Jar :

The Bi-injection is a kind of novel skill to injection two different materials / colors into a mold at separate injection locations, which are controlled independently by two different injection units.

The usage of Bi-injection:

By the skill of bi-injection, perfect combination with different colors of outer and inner layer to present product's uniqueness.

Product specification on Bi-injection:

Please find detailed information by click the link of PP bi-injection cream jar.

The theory of injection molding:

Injection molding is a skill to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them.

Hollow Molding, also known as blow molding, the manufacturer way is inject air into a mold then blow-forming with thermoplastic.

Silkscreen Printing

The part of screen plate is hollow. By using erasing knife to scrape ink on plate which makes ink penetrate on the products.

The way of silk screen printing usually used on text description, Logo design, which is the most common on market.

Apply to surface printing of irregularity and different material, such as curved surface, metal surface, wood, glass, plastic, cloth material and so on.

It needs to proceed with silk screen printing on each color. Below is example of 3 colors silk screen printing / 3 times silk screen printing :

Hot Stamp / Foil

The Hot Stamp / Foil is a kind of special skill on printing who does not need ink, which is supported by specific pressure from temperature, and used on the mold of hot stamping machine that makes printed products and blocking foil compress with each other, and then transfers the content to surface of product according to foil template.

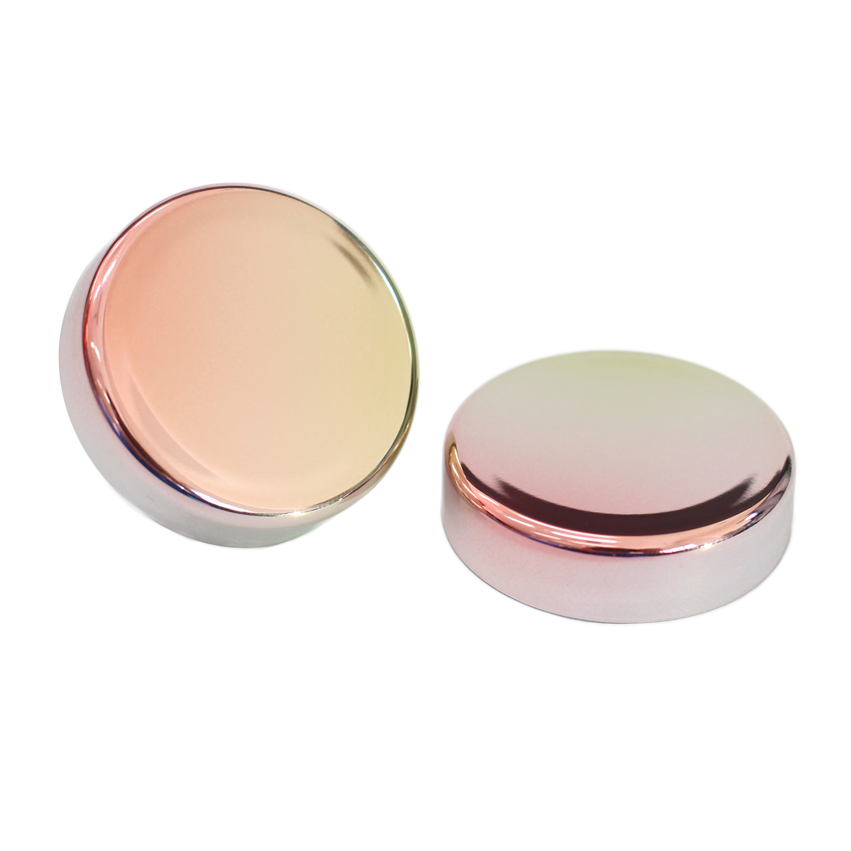

Metallization

To add a layer of electroplating / metal lacquer on surface of plastic products, which presents effect of metalized on products.

Below is examples on bi-colors metallization :